https://groups.yahoo.com/neo/groups/hunter19/conversations/messages/20

Change the backstay to pully system to make it adjustable and so it can tension

the rig for the up wind legs

Fitted quick release jammers on the coach roof bringing all the halyards, spinaker up/down haul

back to the cockpit.

Removable toe strap in the cockpit fitted for a windy day (although one does need to remove the

guard rails to aid leaning out!)

Option 1 – Hull is being cleaned, sanded and so on. After this she is being covered with 5 layers off epoxy coat, and 6 layers off AWL grip 2c. paint

Option 2 – Rubbed down with wet and dry.

Rubbed down with steel wool.

Rubbed down with white spirit (Thinners)

I coat of blue grey Prekote brushed on. No thinners added. He said it

went on like glue.

First coat of Brightside rolled and brushed on. He used a little

amount of thinners. He also used a mini roller and the sheeps wool

type, not the foam type.

Second coat Brightside again with thinners added. Same rollers.

Tinned wire as this does not corrode.

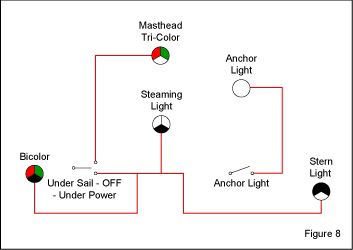

Master & Mast isolator switch.

Solar panel diode built in to prevent nigh-time discharge.

NASA Clipper instruments, “DUET” which combines an echo sounder and log in the same unit. The depth transducer also sits inside the boat in a well of nut oil (this is supposed to be better than bonding it to the boat, however it can be messy!). Hole in the boat for the log!

Transducer just aft of the keel a few inches out from the centre line

Spinnaker using a GRP launching funnel and sock on the pullpit (a common feature on ullswater) the pole is stowed on the boom. Forestay rig tension is adjusted by a ‘Muscle-Box’ mounted on the

deck. The headsail is sheeted in by hand for speed via turning block (no winches) Custom made aluminium foot-pegs in the foot well for stability when she is healed, an aluminium tiller extension and an extra aluminium ‘King-post’ mounted dirctly under the mast foot to cope with the extra rigg tension for racing. She also has a cascade sysem pulley to tension the backstay and the same for the babystay.

Rub it down and priming yourself, 2 coats , final rub down working thro’ the paper grades from 180 to 400 (white) – 600 (darker colours) then get a one man band sprayer in, i know one, very reasonable,

with a poly tunnel or make shift gazebo/tent he could properly do it in the garden

we are not talking large areas, only aprox 0.6m waterline to sheerline ! x 12m